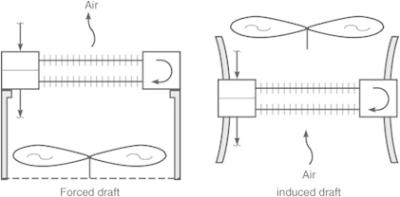

Most air coolers are either induced-draft or forced-draft, as shown in Fig. 17.1, the more common arrangement being forced draft. The air is moved by rather large fans. The tubes are surrounded with foil-type fins, typically 1 in high. The surface area of the fins as compared to the surface area of the tubes is typically 12 to 1. That is why we call an air cooler an extended-surface heat exchanger.

Figure 17.1: Two types of air coolers.

The heat-transfer coefficient of an air cooler (Btu, per hour, per square foot of finned area, per degree Fahrenheit) is not particularly good. It might be 3 to 4 for cooling a viscous liquid, or 10 to 12 for condensing a clean vapor. The low heat-transfer coefficients are offset by the large extended surface area.

Air cooled Heat Exchangers (or) Fin fan Cooler or Air Fin Cooler are the same Air Cooling equipment. In some part of the world Air Cooled Heat Exchangers are also known as Air Fin Cooler. Simply says Air Fin cooler, Fin Fan cooler, Coil Cooler, Dry Cooling Tower are the other names of Air Cooled Heat Exchangers. It also used for Heat rejecting from a hot process fluid to the surrounding atmosphere by using the atmospheric air as a cooling media.

The Air Fin Coolers are basically designed with multiple rows of finned tubes in a series of surface and required numbers of fans are used to move the low temperature atmospheric ambient air over the finned tube coil surface in order to cool the hotter fluid media. It is nothing but an extended type of industrial or automotive radiators. The finned tube bundles are modular construction for easy transportation. The various types of headers are Welded Bonnet Header, Plug Header, Manifold header, Plug and pipe header etc.,

The various types of Fins are 'L' type Wrap-On Fins, 'G' type Embedded Fins and Bi-metallic Extruded Fins etc.,. In some small type heat Exchanger wire/ strip type copper wounded / knurled Fins are also used. Other than finned tube bundle and headers, Axial flow fans and drives etc are used as per the Cooler requirement.

These Air Cooled Type Heat Exchangers are used in oil, gas, petrochemical, refinery, power and condensation plants. All type of fluids in process industries are cooled in Air Fin Coolers with the use of atmospheric air, as the cooling media which resulting in economy in running costs.

Our Air Cooled Heat Exchangers are used for high pressure, high temperature applications in process industries with metallurgy suitable for highly corrosive fluid medias.

In our Air cooled Heat Exchanger division, we manufacture

Process Coolers,

Compressor Coolers,

Radiator Coolers,

Economizers,

Coil Coolers,

Auxiliary Coolers,

Finned Tube Coolers,

Tube Bundles,

Fin to Air Coolers,

Air Blast Oil Coolers

Suitable for all Process Industries, Gensets, Furnaces, Oil and Gas, Refinery, Petrochemical and Power plants etc.,

Very informative and creative content. This concept is a good way to enhance the knowledge.thanks for sharing Air Fin Cooler

ReplyDeleteGreat Article… I love to read your articles because your writing style is too good.

ReplyDeleteFin Fan Cooler